- PRODUCTS

- Product Index

- Product Index

- New & Featured Instruments

- By Test Standard

- ISO Standards

- ASTM Standards

- TAPPI Standards

- Other Standards

- Testing Software

- Datashield

-

SOLUTIONS

- Classified by packaging materials

- Bag packaging

- Bottle / barrel container

- Carton Packaging

- Packaging Solutions

- Bag packaging

- Bottle/barrel container

- Carton

- Fine Chemicals

- Fine Chemicals

- Medical device Solutions

- Medical device packaging

- Special medical equipment

- Solutions for Researching Institutes

- Solutions for Researching Institutes

- Solutions for Inspection Institutions

- Solutions for Inspection Institutions

- TESTING SERVICES

- NEWS & EVENTS

- ABOUT US

- CONTACT US

- ADD FAVORITES

- LANGUAGE

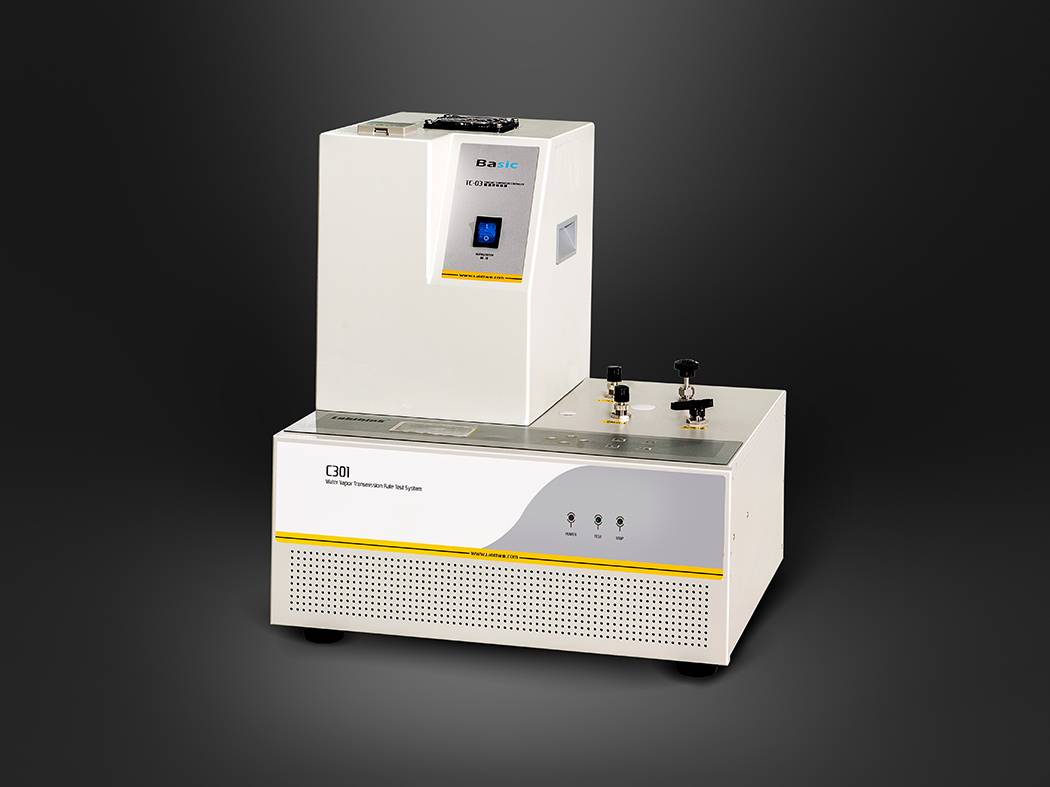

C301H Water Vapor Transmission Rate Test System

C301H Water Vapor Transmission Rate Test System is based on the test principle of infrared water sensor, designed and manufactured according to ASTM F1249, ISO 15106-2, etc., providing high precision and high efficiency water vapor transmission rate test for high and medium barrier materials. It is suitable for the water vapor transmission performance tests of film, containers, sheet and related materials in the fields of pharmaceutical, food, medical devices, daily chemistry, photovoltaic, electronics, etc.

Product Characteristics Note 1

Infrared Moisture Sensor

- Labthink patented infrared moisture sensor achieving a lower test limit.

- Designed according to ASTM F1249.

- Super-long service life, non-consumption type.

- Equipped with over-limit alarm and automatic protection function.

Precise Data

- Using 360° airflow circulation constant temperature technology with better temperature stability.

- Automatic control of carrier gas flow and temperature in test process with higher accuracy.

- Using the universal humidity generating principle of NIST with constant humidity.

- Equipped with imported high-precision temperature and humidity sensors as well as control system with real-time monitoring of temperature and humidity changes.

- Labthink independently developed gas purification device can remove trace oxygen from nitrogen and provide anaerobic carrier gas (Optional).

- The system can achieve a higher test repeatability of 0.005 g/(m2·day)..

Dual-Testing for Film & Container

- In the same test cabinet, film and container are tested respectively to ensure a consistent test environment.

- New patented dual-function test cell for quick switching between functions.

- Automatic translation technology of test cell with widened operating spaces.

- Automatic clamping saves time and labor; clamping strength is consistent with better sealing and no safety risk.

Smart Control

- Color industrial-grade touching screen and desktop operating system, simple and convenient.

- Fully automatic testing and data saving with no manual intervention.

- The system is equipped with various sensors for intelligent reminding and safer control.

- Built-in calendar, multi-language switch, multi-level authority management and other functions.

- Can be connected to needle micro printer for the output of test results, and the results can be stored for a long time (optional).

- The system is embedded network port, which is convenient for external access, data transmission and remote upgrading.

Multi-mainframe Connectable

- New generation platform computer software (Optional).

- One computer can be interconnected to multiple system mainframes.

- The software can independently control each mainframe, and the test data is centrally managed by the platform.

- The software displays real-time water vapor transmission rate curve, water vapor transmission rate coefficient curve, temperature curve and humidity curve.

- Professional test mode provides flexible and rich control functions to meet the needs for scientific research.

- It meets the requirements of GMP for data traceability and meets the needs of the pharmaceutical industry. (Optional)

- DataShieldTM Data Shield System is convenient for centralized data management and connecting information system. (Optional)

Low-Carbon & Energy-Saving

- Intelligent frequency conversion control technology makes the system operate with low power consumption.

- The system can test independently without computer.

- No need for professional constant temperature laboratory while stable test data can be obtained and costs of laboratory construction and daily energy consumption can be reduced.

- Select world famous brand low energy consumption components with stable and reliable performances.

Principle

The prepared sample is clamped between the test chambers. Nitrogen with stable relative humidity flows on one side of the film, and dry nitrogen flows on the other side of the film. Due to the humidity difference, water vapor diffuses through the film to the low humidity side from the high humidity side. On the low humidity side, the water vapor is carried by the flowing dry nitrogen to the infrared moisture sensor, and different water vapor concentrations generates different light signals. By analysis and calculation, the concentration value can be obtained and water vapor transmission rate of the sample can be further determined.

Standards

ASTM F1249, ISO 15106-2, GB/T 26253, GB/T 31355, JIS K7129, YBB00092003

Applications note 1

This test instrument is applicable to the determination of oxygen permeability of:

| Basic Applications |

|---|

Water vapor transmission rate tests of various plastic film, plastic composite film, paper-plastic composite film, co-extrusion film, aluminum-plated film, aluminum foil composite film, glass fiber aluminum foil composite film and other film materials. |

Water vapor transmission rate tests of pharmaceutical packaging, wine bottles, coke bottles, peanut oil barrels, Tetra Pak packaging, vacuum pouches, three-piece cans, cosmetics packaging, toothpaste hose, jelly cups and yogurt cups and other bottles, pouches, cans, boxes and barrels that are made of plastics, rubber, paper, plastic composite, glass, metal, etc. |

Water vapor transmission rate test of PP sheet, PVC sheet, PVDC sheet, metal foil sheet, rubber sheet and silicon sheet materials. |

| Extended Applications |

Water vapor transmission performance tests of various container closures. |

Water vapor transmission performance tests of LCD display screen and related diaphragm plate. |

Water vapor transmission performance tests of solar back panel and related materials. |

Water vapor transmission performance tests of PPR pipe and pipes of other materials. |

integral water vapor transmission performance tests of pharmaceutical blisters. |

Water vapor transmission performance tests of sterile protective film, medical plaster patch, etc. |

Water vapor transmission performance of battery covers and separators. |

Technical Specifications

Table 1: Test Parameters note 2

| Parameter \ Model | C301H | |

|---|---|---|

| Test Range | g/(m2·d) (Standard area is 50cm2) | 0.005~50 |

| g/(pkg·day) | 0.00002~0.25 | |

| g/(m2·d) (MASK area is 5cm2)) | 0.2~500 (Optional) | |

| Resolution | g/(m2·day) | 0.0001 |

| Repeatability | g/(m2·day) | 0.005 or 2%, take the larger one |

| Test Temperature | °C | 15~50 |

| Temp. Fluctuation | °C | ±0.2 |

| Test Humidity | RH | 0%, 35-90% ± 2% (Standard)100% (Optional) |

| Additional Functions | GP-02 Gas Purification Device | Optional |

| DataShieldTM Note3 | Optional | |

| Computer System required by GMP | Optional | |

| CFR21 Part11 | Optional |

Table 2: Technical Specifications

| Test Chamber | 1 set for films + 1 set for containers |

| Film Size | 4.2” x 4.2” (10.6cm×10.6cm) |

| Film Thickness | ≤120 Mil (3mm) |

| Container Size | ≤Φ 100 mm x 250mm; Φ15mm ≤ bottle mouth ≤ Φ 65mm |

| Standard Test Area | 50 cm2 |

| Carrier Gas | 99.999% high purity nitrogen (Gas source is provided by the user) |

| Carrier Gas Pressure | ≥ 40.6 PSI / 280 KPa |

| Port Size | 1/8 inch metal tubing |

| Dimensions | 26.7” H x 14.9” W x 22.8” D (68cm× 38cm× 58cm) |

| Power | 120VAC ± 10% 60Hz / 220VAC ± 10% 50Hz (alternative) |

| Net Weight | 150Lbs (68kg) |

Configurations

- Standard Configurations

- Mainframe, sampler, vacuum grease, Φ4 mm polyurethane tube

- Optional Parts

- Software, computer, GMP computer system requirements, CFR21Part11, air compressor, GP-02, DataShieldTM Note3

- Note

- 1. The gas supply port of this instrument is Φ4mm PU Tubing(pressure 79.7 PSI / 550 KPa);

2. Customers need to prepare gas supply.

Note 1: The described product characteristics are subject to the specific annotation of the "Technical Parameters".

Note 2: The parameters in the table are measured in Labthink laboratory by professional operators according to the requirements and conditions of the relevant laboratory environment standards.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

We can help you select or customize the proper unit for your test requirements.

Related Products

Product Categories

Search Products

Need help or have a question? For more information on how Labthink can help your company profit through testing, please Click the button.