- PRODUCTS

- Product Index

- Product Index

- New & Featured Instruments

- By Test Standard

- ISO Standards

- ASTM Standards

- TAPPI Standards

- Other Standards

- Testing Software

- Datashield

-

SOLUTIONS

- Classified by packaging materials

- Bag packaging

- Bottle / barrel container

- Carton Packaging

- Packaging Solutions

- Bag packaging

- Bottle/barrel container

- Carton

- Fine Chemicals

- Fine Chemicals

- Medical device Solutions

- Medical device packaging

- Special medical equipment

- Solutions for Researching Institutes

- Solutions for Researching Institutes

- Solutions for Inspection Institutions

- Solutions for Inspection Institutions

- TESTING SERVICES

- NEWS & EVENTS

- ABOUT US

- CONTACT US

- ADD FAVORITES

- LANGUAGE

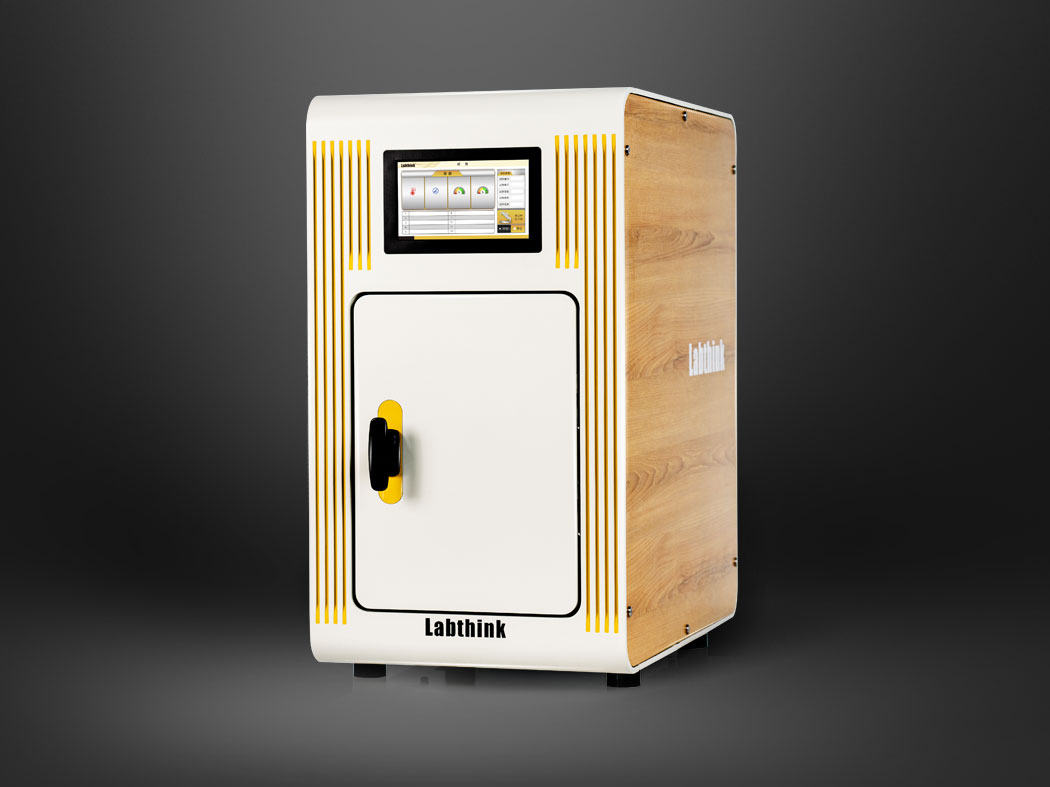

C101H Gas Transmission Rate Test System

C101H Gas Transmission Rate Test System, based on the test principle of differential pressure method, is professionally suitable for the determination of gas transmission rate, solubility coefficient, diffusion coefficient and permeability coefficient at varied temperatures of plastic film, containers, composite film, high barrier materials, sheet, metal foil, etc. The test system conforms to GB, ISO, ASTM and other national and international standards.

Product Characteristics Note 1

Precise Data

- Imported high precision vacuum sensor for accurate and repeatable test of high barrier materials.

- Automatic pressure compensation technology in the test process with constant pressure difference.

- Imported temperature control system to ensure temperature control accuracy.

- Use 360° airflow circulation constant temperature technology with better temperature stability.

- Imported pneumatic control system with ultra-low failure rate and super long service life to ensure that the overall system is well sealed.

- Reference films for rapid calibration are provided to ensure accuracy and versatility of the test data.

Dual-Testing for Film & Container

- In the same test cabinet, film and container samples are tested independently to ensure a consistent test environment.

- New patent dual-function test cell can realize quick switching between functions.

- Automatic translation technology is applied in the test cell, and the operating space is widened.

- Automatic clamping saves time and labor; clamping strength is consistent with better sealing and with no safety risk.

- Test time of medium and low barrier film materials < 4 hours (including vacuuming time).

- Test time of high barrier film materials < 8 hours (including vacuuming time).

Smart Control

- Color industrial-grade touching screen and desktop operating system, simple and convenient.

- Fully automatic testing and data saving with no manual intervention.

- Check port is available for quick calibration.

- Test system is equipped with various sensors for intelligent reminding and safer control.

- Built-in calendar, multi-language switch, multi-level authority management and other functions.

- Can be connected to a needle micro printer for the output of test results to realize long term result storage (Optional).

- Test system is embedded with network port, which is convenient for external access, data transmission and remote upgrading.

Multi-System Connectable

- New generation platform computer software (Optional).

- One computer can be interconnected with multiple test system mainframes.

- The software can independently control each mainframe, and the test data is centrally managed by the platform.

- The software displays real-time pressure-time curve, transmission rate-time curve, and temperature-time curve.

- Research test mode of the software provides flexible parameter setting and function setting, which is easy to analyze gas transmission rate, solubility coefficient, diffusion coefficient and permeability coefficient of the sample.

- The test system meets the requirements of GMP for data traceability and meets the needs of the pharmaceutical industry (Optional).

- DataShieldTM Data Shield System is convenient for centralized data management and information system connection (Optional).

Extensive Functions

- The system supports tests of single gas and mixed gas as well as flammable and explosive dangerous gases.(System for dangerous gas needs to be customized.)

- The system can test gases of different humidity levels with automatic and precise control and no manual intervention. (Customized)

- Innovative data fitting function can fit the gas transmission rate, permeability coefficient, solubility coefficient, and diffusion coefficient of materials at the ultimate temperature.

- The test system truly meets the requirements of the differential pressure method test standard, and can be measured.

Low-Carbon & Energy-Saving

- Intelligent frequency conversion control technology makes the system operate with low power consumption.

- Vacuum pump automatic start and stop control technology is energy saving.

- Without computer, the test system can complete tests independently.

- No need for a professional constant temperature laboratory while stable test data can be obtained with low costs for laboratory construction and daily energy consumption.

- Manufactured with world famous brand low energy consumption components with stable and reliable performance.

Principle

C101H adopts the test principle of differential pressure method. The prepared sample is placed between the upper and lower test chambers and clamped. Vacuum the low-pressure chamber (lower chamber) and then vacuum the whole system. When achieving specified vacuum degree, close the lower chamber and fill the upper chamber (high-pressure chamber) with test gas at a certain pressure. Ensure a constant pressure difference (adjustable) is formed on both sides of the sample. The gas will permeate from the high-pressure side to the low-pressure side under the differential pressure gradient. Thus, by analyzing the internal pressure on the low-pressure side, the barrier parameters of the sample can be obtained.

Standards

ISO 15105-1, ISO 2556, GB/T 1038, ASTM D1434, JIS K7126-1, YBB 00082003

Applications note 1

This test instrument is applicable to the determination of oxygen permeability of:

| Basic Applications |

|---|

Suitable for gas permeability tests of plastic film, plastic composite film, paper-plastic composite film, co-extrusion film, aluminum coated film, aluminum foil, aluminum foil composite film and other materials. |

Suitable for gas permeability tests of pharmaceutical packaging, bottles, coke bottles, Tetra Pak packaging, vacuum pouches, three-piece cans, cosmetic packaging, toothpaste tube, jelly cups, yogurt cups and other bottles, bags, cans, boxes, buckets made of plastics, rubber, paper, paper-plastic composite, glass and metal. |

Suitable for gas permeability tests for engineering plastics, rubber, building materials and other sheet materials such as PP sheet, PVC sheet, PVDC sheet, etc. |

| Extended Applications |

Oxygen transmission performance tests of various packaging closures. |

Suitable for the permeability tests of various gases, such as oxygen, carbon dioxide, nitrogen, air, helium, etc. |

Suitable for the permeability tests for various films of flammable, explosive or toxic gases. |

Suitable for the gas permeability tests of biodegradable films, such as starch biodegradable pouches. |

Suitable for gas permeability tests of aerospace materials, such as helium permeability test of airship airbags. |

Suitable for gas permeability tests of paper and paper-plastic composite materials, such as cigarette wrapped aluminum foil, Tetra Pak sheet, instant noodle paper bowl,and disposable paper cup, etc. |

Suitable for gas permeability tests of paint films on the substrate. |

Suitable for gas permeability tests of glass fiber cloth, glass fiber paper and other materials, such as Teflon coating, Teflon high temperature coated fabrics, fluorine silicone cloth, etc |

Suitable for gas permeability tests of cosmetics hoses, aluminum plastic pipe, toothpaste tube sheet. |

Suitable for tests of all kinds of rubber sheets, such as for automobile tire gas permeability test. |

Technical Specifications

Table 1: Test Parameters note 2

| Parameter \ Model | C101H | |

|---|---|---|

| Test Range | cm3/m2·24h·01MPa | 0.01~50,000 |

| cm3/pkg·24h·01MPa | 0.00005~250 (Customized) | |

| cm3/m2·24h·01MPa | 0.01~500,000 (Optional) | |

| Resolution | cm3/m2·24h·01MPa | 0.001 |

| Test Temperature | °C | 15~50 |

| Temp. Resolution | °C | 0.1 |

| Temp. Fluctuation | °C | ±0.2 |

| Test Cell Vacuum Degree | Pa | <10 |

| Vacuum Resolution | Pa | 0.05 |

| Test Pressure Range | KPa | 10~190 |

| Test Pressure Resolution | KPa | 0.01 |

| Humidity Range | %RH | 0%, 35-90% ± 2% (Customized) |

| Additional Functions | DataShieldTM Note3 | Optional |

| Computer System required by GMP | Optional | |

| CFR21 Part11 | Optional |

Table 2: Technical Specifications

| Test Chamber | 1 set for film (Standard configuration) 1 set for containers (Customized configuration) |

| Film Size | 4.2” x 4.2” (10.6cm×10.6cm) |

| Film Thickness | ≤120 Mil (3mm) |

| Container Size | ≤Φ 100 mm x 250mm; Φ15mm ≤ bottle mouth ≤ Φ 65mm |

| Standard Test Area | 50 cm2 |

| Gas Specifications | Oxygen, nitrogen, carbon dioxide, etc. (Gas source is provided by the user) |

| Gas Source Pressure | 72.5 PSI / 500 KPa |

| Port Size | Φ4 mm Polyurethane tube |

| Dimensions | 26.7” H x 14.9” W x 22.8” D (68cm× 38cm× 58cm) |

| Power | 120VAC ± 10% 60Hz / 220VAC ± 10% 50Hz (alternative) |

| Net Weight | 150Lbs (68kg) |

Configurations

- Standard Configurations

- Mainframe, vacuum pump, sampler, vacuum grease, filter paper, Φ4mm polyurethane tube

- Optional Parts

- Software, computer, GMP computer system requirements, CFR21Part11, air compressor, DataShieldTM Note3

- Note

- 1. The gas supply port of this instrument is Φ4mm PU Tubing(pressure 79.7 PSI / 550 KPa);

2. Customers need to prepare gas supply.

Note 1: The described product characteristics are subject to the specific annotation of the "Technical Parameters".

Note 2: The parameters in the table are measured in Labthink laboratory by professional operators according to the requirements and conditions of the relevant laboratory environment standards.

Note 3: DataShieldTM provides safe and reliable data application support. Multiple Labthink instruments can share one single DataShieldTM system which can be configured as required.

We can help you select or customize the proper unit for your test requirements.

Related Products

Product Categories

Search Products

Need help or have a question? For more information on how Labthink can help your company profit through testing, please Click the button.