- PRODUCTS

- Product Index

- Product Index

- New & Featured Instruments

- By Test Standard

- ISO Standards

- ASTM Standards

- TAPPI Standards

- Other Standards

- Testing Software

- Datashield

-

SOLUTIONS

- Classified by packaging materials

- Bag packaging

- Bottle / barrel container

- Carton Packaging

- Packaging Solutions

- Bag packaging

- Bottle/barrel container

- Carton

- Fine Chemicals

- Fine Chemicals

- Medical device Solutions

- Medical device packaging

- Special medical equipment

- Solutions for Researching Institutes

- Solutions for Researching Institutes

- Solutions for Inspection Institutions

- Solutions for Inspection Institutions

- TESTING SERVICES

- NEWS & EVENTS

- ABOUT US

- CONTACT US

- ADD FAVORITES

- LANGUAGE

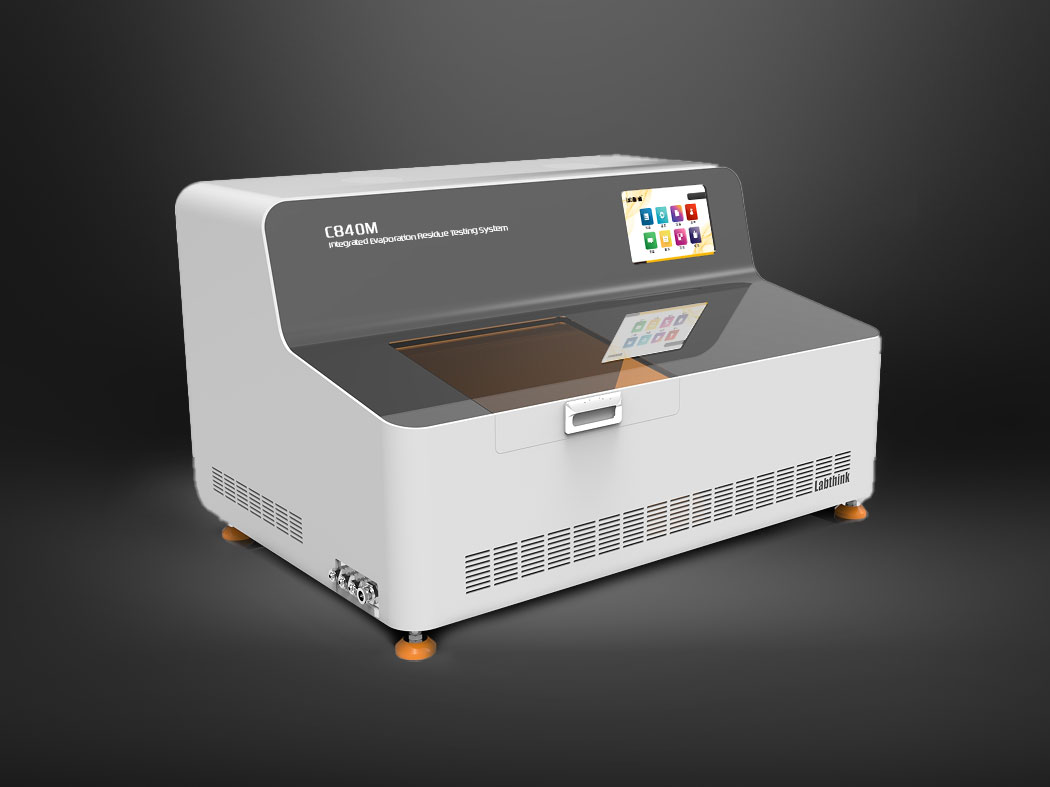

C840M Integrated Evaporation Residue Testing System

C840M Integrated Evaporation Residue Testing System is designed and produced based on the principle of Gravimetric Method and testing standards for plastic packaging, Pharmacopoeia and chemical reagents, etc. It is professionally suitable for the determination of evaporation residue of food or pharmaceutical packaging, total migration of food contact or pharmaceutical contact materials or products, and evaporation residue of chemical reagents and purified water.

Characteristics Note 1

Traceable Data

Safe & Compliant

Intelligent Control

Testing Principles

Sample is soaked in the solution, which is the simulator of various foods. When the solution is evaporated and dried, the total migration amount of non-volatile matter can be obtained.

Sample is soaked in solution required by the standards. After the soaking solution and blank solution are evaporated and dried, the total weight of non-volatile residue is obtained by comparing with the blank solution.

Test Standard Compliance

Pharmacopoeia, YBB00342002-2015, YBB00132002-2015 and other standards for pharmaceutical production and pharmaceutical packaging.

ISO 759-1981, GB 31604.8-2016, GB/T 5009.60 and other standards for food contact materials.

GB/T 9740 and other related standards for determination of chemical reagent residue after evaporation.

Applications

Basic Applications | Purified Water | Determination of non-volatile matters in purified water for pharmaceutical applications. |

Extensive Applications | Pharmaceutical Packaging Materials | Determination of non-volatile matters of various pharmaceutical composite films, bags, bottles, rubber plugs and caps. |

Food Contact Materials | Determination of the total migration amount of polyethylene, polystyrene, polyvinyl chloride, polypropylene, melamine, foam polystyrene and plant fiber molding products. | |

Chemical Reagents | Determination of various chemical reagent residue after evaporation. |

Technical Parameters

Table 1: Test Parameters Note 2

Parameter\Model | C840M | |

Test Range | mg | 0.3~80000 |

0.05~10000 (optional) | ||

Resolution | mg | 0.1 |

0.01 (optional) | ||

Repeatability | mg | ±0.3 |

±0.05 (optional) | ||

Temperature Range | ℃ | Room temperature~130 |

Temperature Fluctuation | ℃ | ±0.5 |

Extended Functions | 21 CFR Part11 | optional |

Computer system requirements for GMP | optional | |

Table 2: Technical Specifications

Test Stations | 12 |

Test Cup Volume | 100mLNote 3 |

Gas Specifications | Compressed air (gas source is provided by the user) |

Gas Source Pressure | ≥ 72.5 PSI/500 kPa |

Port Size | Φ8mm Polyurethane tube |

Instrument Host Dimensions | 24.8” H x 41.3” W x 28.7” D (63cm× 105cm× 73cm) |

Power Supply | 120VAC±10% 60Hz / 220VAC±10% 50Hz (Select one from the two) |

Net Weight | 396Lbs (180kg) |

Table 3: Product Configuration

Standard Configuration | Instrument host, scale (0.1mg), reagent collection module, liquid cooling module, test cups (12 cups), Φ8 mm Polyurethane tube |

Optional Parts | Software, computer system requirements for GMP, 21 CFR Part11, air compressor (with an exhaust capacity > 200L/min), test cup (100mL), scale (0.01mg), weight (50g), air drying module |

Note1: The described product characteristics are subject to the specific annotation of the "Technical Parameters" table.

Note2: The parameters in the table are measured in Labthink laboratory by professional operators as per requirements and conditions of the relevant laboratory environment standards.

Note3: The test cup volume can be customized, but the test range may be subject to actual delivery.

Labthink is always dedicated to the innovation and improvement of product performance and functions. Therefore, technical specifications are subject to change without further notice. Labthink reserves the rights of final interpretation and revision.

Related Products

Product Categories

Search Products

Need help or have a question? For more information on how Labthink can help your company profit through testing, please Click the button.